|

Building a 4mm finescale model railway which has its basis on a

planned (but never built) railway line that never actually served the

villages of Ewhurst and Ewhurst Green in Surrey! |

|

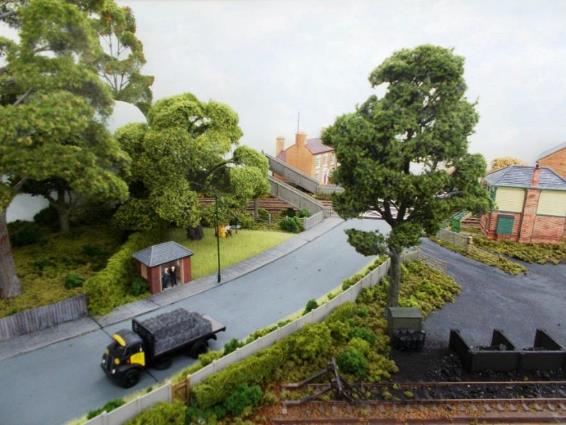

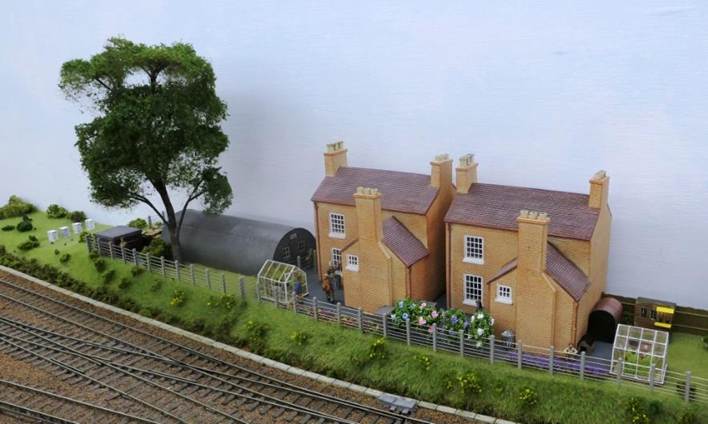

Ewhurst Green’s

station building as repainted and detailed. The platform at this location is

brick-faced with the concrete harp-and-slab construction making an appearance

with both the later-built country-end platform extensions and Up Passenger

Loop. |

Fellow Finescale Modellers,

This webpage is regularly updated as the layout

progresses.

Moving house in August 2013 to a secluded bungalow

just 440-yards from the beach (as the gull flies) brought an end to 4mm layout Apothecary Street (named after a short-lived London

junction outside Holborn Viaduct station upon where the model drew inspiration)

but provided the opportunity for a new layout, Ewhurst Green .

With my modelling deeply rooted in British Rail’s Southern Region, a design was needed that would permit operation

of full-length trains at a location which could encompass traffic from at least

two of the Southern Region’s divisions. Furthermore, the layout needed to

be operated by just one person (if required) mindful there is a limit to the

number of trains that can be realistically controlled at any moment in time.

A tall order which led to Ewhurst Green ; a

model railway which has its basis on several planned (but never built) railway

schemes in Surrey (including a c.1884 proposal from Dorking) that may have

served the villages of Ewhurst and Ewhurst Green (as a junction for Cranleigh and Guildford) on its route down

through Midhurst to conceivable join the railway along the coast near Havant, thence onto Portsmouth and Southampton. Ewhurst Green was

also in an area with which I had many past associations several decades ago.

Had a direct railway from London ever served

Ewhurst and Ewhurst Green, then it is likely these villages would have

significantly increased in size and (by virtue of the station’s goods

yard facilities) potentially attracted some local industry befitting this

(otherwise) rural area.

With Up and Down Main Lines operational, the Ewhurst Green running sessions were proving extremely popular with East Sussex

Finescale group members; particularly following lunch at our local beachfront

café under a mile away until the pandemic struck in late 2019!

However, many short video clips are regularly

uploaded to Ewhurst Green’s channel on YouTube although this is

now proving difficult to use and may be archived.

https://www.youtube.com/@ewhurstgreen

Enjoy Colin!

|

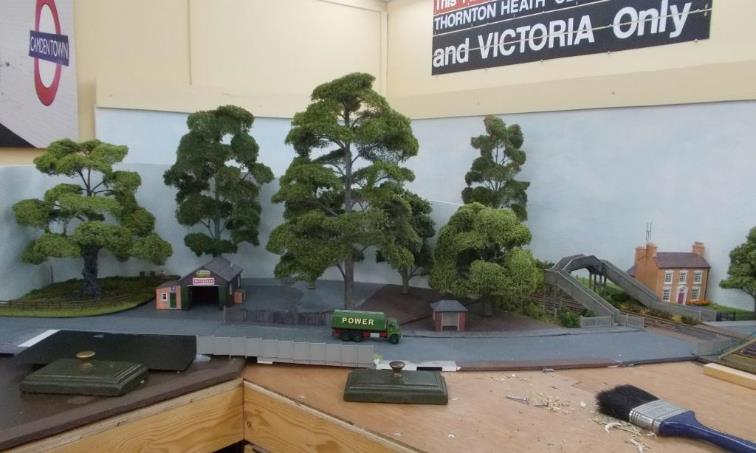

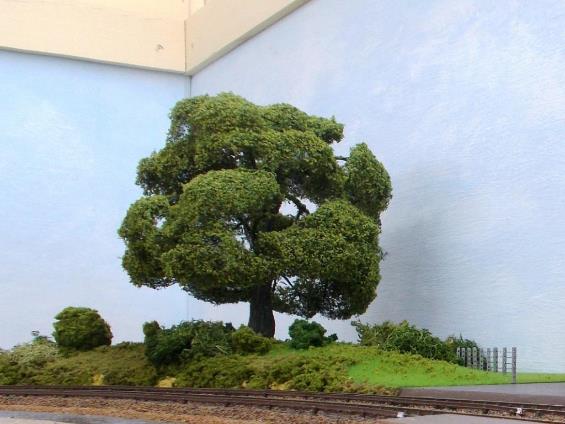

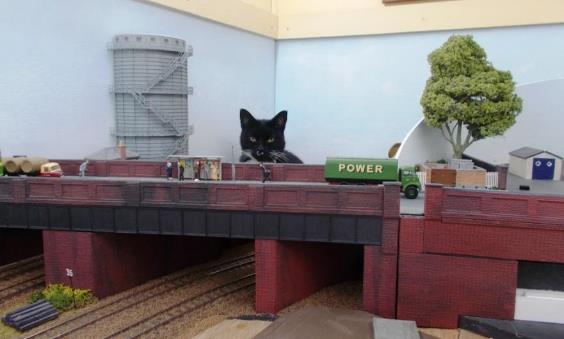

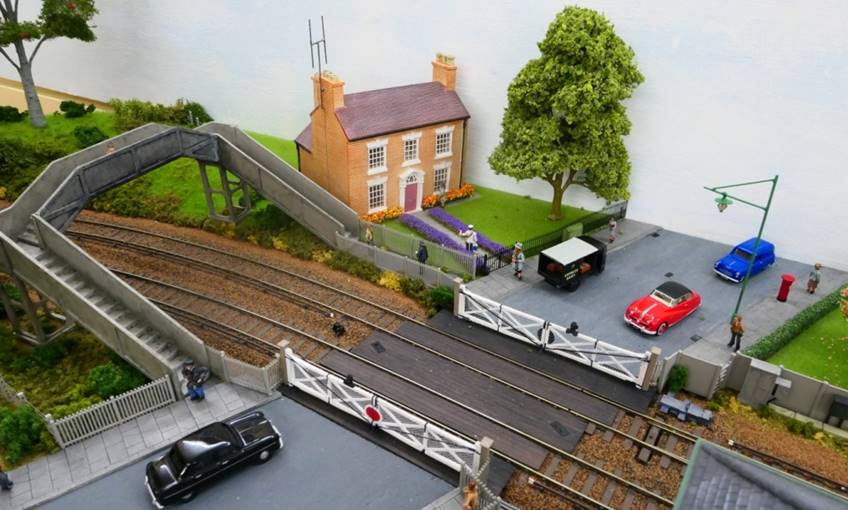

Country-end of Ewhurst Green with the separate spans of the road

bridge across the electrified main line to the coast and the Cranleigh branch

which curves away to the right behind the sub-station. The agricultural works

alongside the headshunt distracts from the otherwise semi-rural area.. |

Some layout descriptions commence with baseboard

construction. However, before any of this this happens it is important to

decide exactly what one is intending to model and how reasonably prototypical

operation could be achieved within the physical space available. In this

respect it is necessary to consider the model, not in isolation but as part of

the regional network within which it is located including its rail services,

even a reasonably viable timetable. Accordingly, our starting point is the

Layout Concept. However, readers are welcome to head straight to any of the

chapters listed below:

|

|

||||

One

|

With Maunsell

Pull-Push set 619 in the Down Headshunt, set 607 is propelled past on an Up

service by M7 no.30051. Set 607

was damaged at Eastbourne on 13th September 1961 and subsequently

disbanded. BCK 6682 was scrapped with the SO to Loose working the rest of its

days as a pull-push trailer on the Lymington branch. Both expertly weathered by TMC, set 607 was additionally renumbered as

this was not in Hornby’s range. Headcode discs are still to be fitted

to these models. On branch lines these sets often sported both a headcode

with a tail lamp! |

Southern Region

With any model railway the starting point ought to

be what does a railway-modeller want in terms of a model (whilst being mindful

of constraints such as space and budget)?

As a railwayman who followed his grandparents onto

the Southern (in my case British Rail’s Southern Region rather than the

Southern Railway) my modelling interests are fairly-well cast-in-stone. The

previous (terminal layout) Apothecary Street had been constructed as a parody

of Holborn Viaduct with cross-London freights via Snow Hill tunnel and

expanding this concept was considered.

However, in recent years the range of Southern

models that have become available make modelling of the Southern Region’s

divisions relatively straightforward, even before the many offerings by kit

manufacturers is considered. So, when Bachmann had brought out its marvellous

model of Thomas Myres 1880-1883 LBSCR station buildings the opportunity to utilise one of

these couldn’t be ignored.

Geographical Location

In building a model railway, one really important

factor is its geographical location; in the case of Ewhurst Green somewhere on

the former Southern Region (obviously). Even then there were distinct

differences between the South Western, Central and South Eastern Divisions and

could a model which could realistically incorporate stock from all three

Divisions (SWD, CD and SED) be created whilst using the Thomas Myres ex. LBSCR

station building?

|

The Up Side waiting

room and subway cover (as modified and repainted) awaiting completion of the

station’s platforms. |

Thomas Myres

Thomas Myres was first asked to

design the replacement station building at Hassocks (1880), thence those

required for the secondary railway lines built in East and West Sussex Hailsham

to Eridge (1880), Chichester to Midhurst (1881), Lewes to East Grinstead (1882)

and Haywards Heath to Horsted Keynes (1883); a total of eighteen buildings.

Ewhurst Green’s replacement station building could have made the total

nineteen; perhaps more with other stations along the route !

Use of this building design would set the layout

firmly in Central Division (ex. LBSCR) territory with some limited scope for

South Western or South Eastern Division workings. However, historical design

along with a sprinkling of modeller’s licence can push the bounds whilst

still remaining reasonably credible.

|

Visiting SR Malachite

N15 746 Pendragon hauls set 209 on an Up London service through Ewhurst

Green. |

Credibility

The next stage was to identify a reasonably

credible location for the station and the potential services that could exist.

Obviously, this isn’t an essential step, but it does help in terms of

what type of services could have run and the rolling stock required. A credible

backstory will assist in developing the layout and its design towards providing

a model that will look the part. In this respect railways that were planned but

never built provided inspiration.

However, any station (and the services it could

have seen) would have to be operationally manageable by myself; there is no

point in building a layout that takes a team of operators to run it. On that

basis the favoured option was for a junction station where trains (circulating)

on the Up and Down main line essentially form the backdrop for the branch

line’s operating sequences.

In terms of appearance part of the overall concept

was for none of the scenic track to remain parallel to the track-room’s

rear wall and that a less-is-more approach was intended.

|

Visiting H2 Brighton Atlantic 32424 Beachy Head heads south

through Ewhurst Green. Behind the locomotive is a CCT fitted with cycle

hangers. |

Era

Hassocks Gate station opened on 21st

September 1841; now called Hassocks (code HSK) its first building was to a design by David Mocatta. However, it was Thomas Myres who designed its

replacement which was built between December 1880 & August 1881 by James Longley & Co of

Crawley. Sadly, this

building was also demolished by British Rail in 1973.

Accordingly, with Myres architecture this could

suggest either an opening date of the model railway’s station as being

circa 1880-1884, else a replacement station building being erected during this

period. The date of opening for the railway does provide a degree of historical

context.

Notwithstanding, the actual period being modelled

would be essentially within the period 1954 to 1962 although

concentrating within the middle of that timescale. As the model develops,

thoughts are collecting towards narrowing that timescale down to a specific

year or even having two distinct running periods with slightly differing stock.

Certainly, the scenic details would not significantly change across such a

relatively small period.

|

An unlikely photograph

for a real Ewhurst Green. However, one of the joys of running sessions

permits visiting early BR Blue liveried Merchant Navy 35024 'East Asiatic Company' to pass BR

Green liveried no.35011 General Steam Navigation

; the latter being a recent metal-bodied release under the Hornby-Dublo brand

(albeit in lined blue 3-rail packaging). |

Liveries

In terms of rolling stock quite a few coaches

retained Southern Railway post-war Malachite green into 1956 (some even beyond)

without receiving BR’s Crimson Lake (and Cream). Following the abolition of Second-class on 3rd June 1956 (at which time Third-class was immediately

renamed Second-class), the following month (July 1956) saw significantly

changes to liveries with Crimson Lake (with or without Cream) being rapidly

replaced by Southern Region Green far quicker than would have happened under

the usual ten-year repainting cycle at Lancing Carriage Works (repaints took

place instead of the 2 yearly varnishing).

During 1956 /1957 there was quite a mix of post-war

Malachite Green (with BR typeface), Crimson Lake (and Cream) and BR(S) Green.

Occasionally it was difficult to see a huge difference between post-war

Malachite carrying multiple layers of varnish and BR(S) Green.

1959 was the last year for Maunsell corridor sets

to be seen running in Crimson Lake & Cream (CLC) livery; this also saw the

demise of a lot of non-corridor stock with much still in Crimson Lake (CL).

Nevertheless, on the Southern Region many Mk1 3 Cor & 4 Cor (corridor

coach) sets weren’t repainted CLC to Green until 1961 (a few even lasted

into 1962); this being in part due to the varnishing undertaken at Lancing

Works every two years or so. 1959 also saw the first of the UIC yellow First-class cantrail bands.

A number of Southern Railway steam locomotive

classes were withdrawn very shortly after nationalisation with more

disappearing mid-fifties onward, thence with the stock associated for the 1959

Kent-coast electrification; these all being interesting periods of change.

With such a variation in rolling stock and liveries

it has been decided to keep the period as a concise range (rather than a

specific date) although this range can be narrowed for any given running

session.

Notwithstanding, individual trains are normally

formed of stock that would have run together both in terms of livery and

division. For example BRCW Cromptons would not have

run with a CLC-liveried Maunsell corridor set.

|

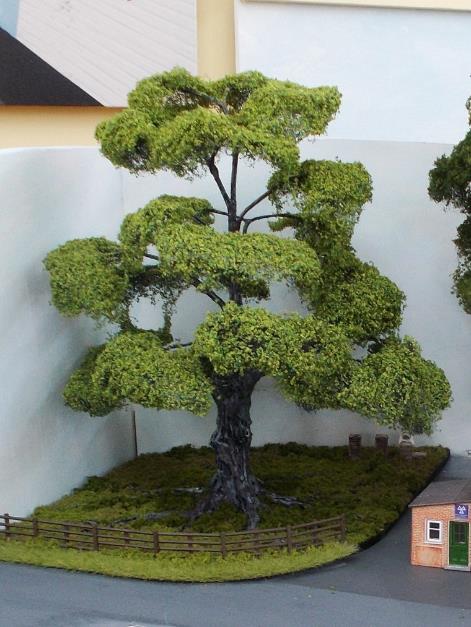

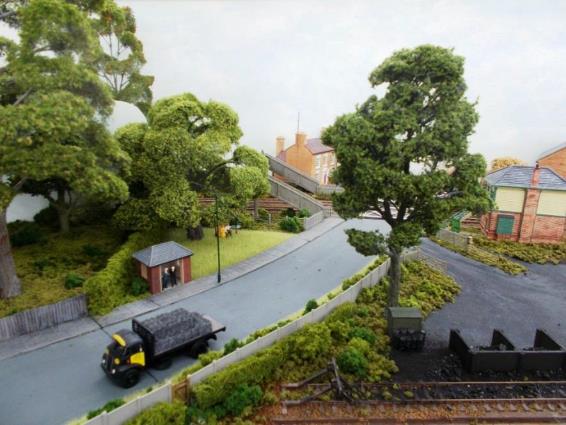

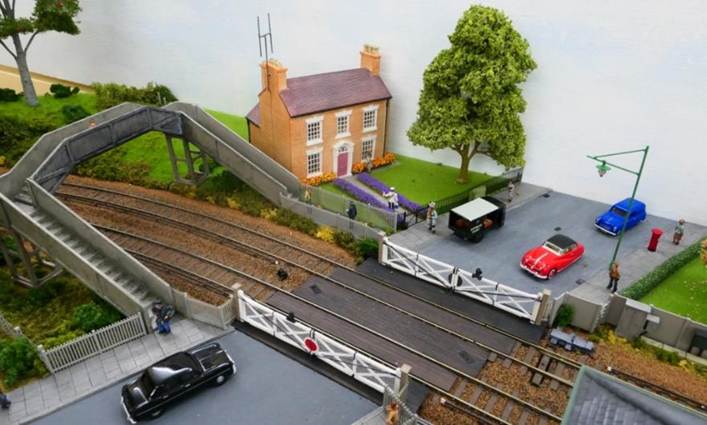

With a tree

temporarily removed from beside the LSWR wooden gates into the coal yard, an

uninterrupted view is enabled of the bus shelter, Level Crossing, concrete

footbridge thence Lavender House with its H type television ariel mounted on

its chimney. |

Less is More

The

room housing Ewhurst Green has considerable length. However, in order to try

and create greater realism, a linear layout with its scenic track parallel to

the back wall of the track room was simply not going to happen.

Firstly,

whilst the central scenic section of the layout is constructed on a straight

32” wide baseboard, the other two-thirds on either side taper outwards to

around five-feet in width (the baseboard design still places everything within

arm’s reach more on this later). This arrangement helps to break up the

otherwise linear appearance of the scenic section.

At

either end, the double-tracked main line curves around from the storage loops

on tracks hidden from view (at the country end the double-tracked branch

similarly curves again out of sight). The scenery is designed to place these

out of immediate view whilst avoiding the old cliché of disappearing

into a tunnel.

However,

once the mainline becomes visible, it comprises two long straights split by a

large radius curve (position mid-way along the station’s platformed

section). This design has a number of benefits with the principle two being:

(1) the main scenic

running lines are not parallel to the rear wall of the model room and

(2) space is created

between the main lines and the back wall for the station building, forecourt

and Down bay platform.

Even

the long retaining wall (with agricultural works atop) is constructed on a

taper relative to the back wall. In terms of railway history, the factory originally stood atop a cutting

and (with the enlargement of the station) the cutting had to be replaced with a

retaining wall in order to enable a headshunt alongside the Down Main.

Visually,

the front of the station building cannot be seen but the (arguably) more

interesting platform side can. In terms of operational accessibility, this

arrangement allows the platform loop and goods loop to be on the

operator’s side of the main line (and station). Furthermore, the tapering

boards can be used for fanning out the station’s goods yard and sidings

whilst leading the scenery into the two curved boards which hide the tracks are

they curve round to the storage loops.

Finally,

the decision was made not to crowd the baseboards with track; once again this

was to try and improve the appearance of realism. As the old adage says,

‘Less is more’.

Two

|

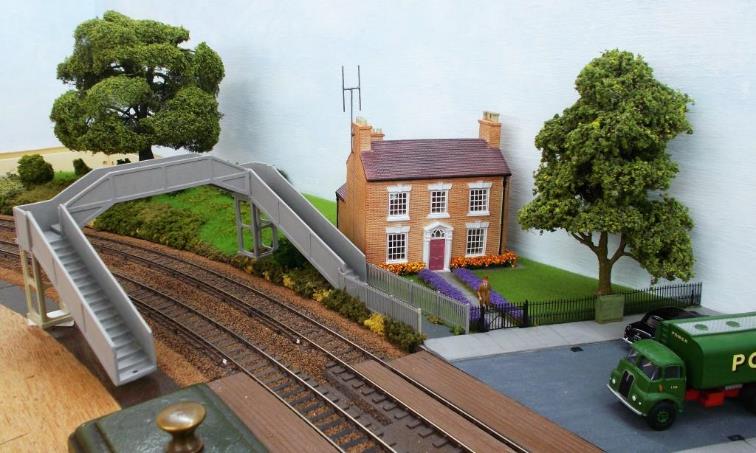

As construction progresses Ewhurst Green is starting to look

greener and far more rural. With the coal yard well underway, the headshunt leading up to

the Signal Box has been laid. Lavender House sits beyond the Level Crossing

now has its MacKenzie & Holland gates. To the right of Cherry Cottage, just visible is the concrete

coal bunker behind the half-buried and overgrown Anderson shelter with garden

shed alongside. Washing is being put out whilst a boy plays with his dog.

Flowers fill the greenhouse just visible on the far right. Behind the greenhouse and tree there is an access road between

the two wooden fences that leads to some lock-up garages & alley to the

station. |

Setting the layout’s location can assist in

its design, so what should a railway-modeller consider?

Having ruled out modelling a real station (I admire

those modellers who do) and based on what was wanted from the model versus the

limited space available, the next best thing would appear to be a credible but

fictitious station at a real location. In this respect it becomes quite

difficult finding such a location, for most candidates already have or had a

station. However, one possible location stood out in terms of a potentially

credible location on a proposed but never built railway line.

Furthermore, the name Ewhurst Green ticked all the

right boxes in terms of an appropriately sounding Southern Region name.

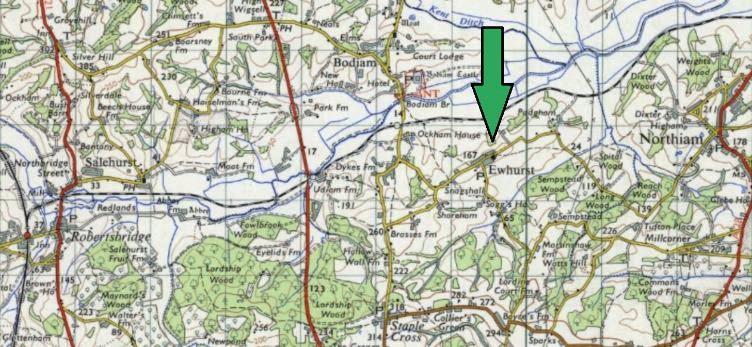

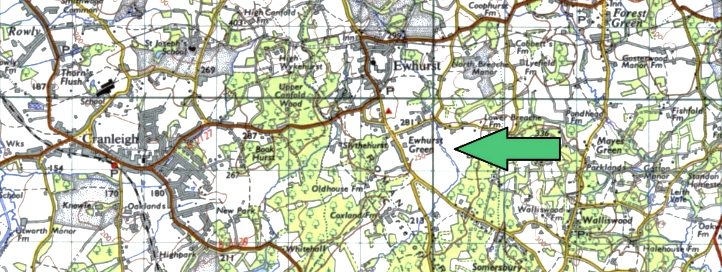

There are two village locations called Ewhurst

Green one in Surrey (near Cranleigh), the other in East Sussex (near Bodium);

thus, providing the opportunity to be slightly indistinct with the location if

ever required. Certainly, Ewhurst Green (and nearby Ewhurst) in Surrey could

have fitted in with unfulfilled c.1884 plans to build a railway from Dorking

serving Cranleigh thence down to Midhurst.

There is also a

Ewhurst Park near Basingstoke and a Ewhurst Manor in the parish of Coneyhurst,

West Sussex (along with a Coneyhurst Manor in the parish of Ewhurst, Surrey).

Whilst both Ewhurst Green locations provide

opportunity for Central & South Eastern Division services, Surrey could

additionally link directly to the South Western Division as well as forming an

alternative route to several important locations, thus opening-up the traffic

passing through the station.

It was equally surprising that the website www.EwhurstGreen.com was available!

East Sussex

Ewhurst Green (East Sussex)

The East Sussex village of Ewhurst Green sits not

too far south-west of the Kent & East Sussex Railway, which at this

location passes east west along the Rother valley at Bodium; this being already

served by a light railway built through relatively a sparsely populated rural

area. The nearest main line to London passed through Robertsbridge situated

between the sizeable towns of Hastings, St Leonards-on-Sea and Royal Tunbridge

Wells. Accordingly, the scope for credibly modelling an ex. LBSCR mainline

railway through this Ewhurst Green was sadly virtually nil.

Surrey

Ewhurst Green (Surrey)

The name Ewhurst

derives from the Old English 'hyrst', meaning 'wooded

hill', and 'iw' meaning 'yew tree'; the first

recorded spelling appears to be Iuherst from 1179.

Historically Surrey’s Ewhurst and Ewhurst

Green may have come close to being served by the railways. In terms of routes

to Midhurst, 1845 saw consideration to build a line from Guildford through

Godalming, Haslemere and Midhurst to Chichester. However, LSWR’s Midhurst

- Petersfield did open in 1864, LBSCR’s Midhurst - Pulborough (Hardham

Junction) in 1866 and Midhurst Chichester in 1881 (the first sod of the latter

having been cut back in 1865 passenger traffic ceasing in 1935). Passengers had

to wait until 1925 for a combined Midhurst station (services to Midhurst were

withdrawn in 1955).

With the SER considering a route from Betchworth to

Portsmouth, Ewhurst Green could have been a junction station on a

thirty-seven-mile LBSCR route between the existing railways at Holmwood and

Westbourne.

Mixing

historical proposals with imagination it is conceivable such a railway line

could have left the Dorking to Horsham Railway at Holmwood passing through a

station at Forest Green to reach Ewhurst Green (due south-southeast of the village). In terms of railway

construction this would have been built late in the day .

A junction

off the London-end of Ewhurst Green station would have permitted the

line across from Warnham and Horsham (passing through Oakwoodhill station) to

join.

Whilst

there could have been a junction at the Country end of Ewhurst Green taking a double-tracked branch-connection across to

the 1865 Horsham to Guildford railway and into station at Cranleigh (itself having become a passing loop in 1880 as those at

Bramley and Baynards were proving insufficient) it is possible that the 1865

route was not built in favour of Horsham Ewhurst Green - Cranleigh.

From Ewhurst Green this main line may have

passed through Loxwood thence Gennets Viaduct across the valley (both Wey & Arun

Junction Canal and the River Arun) to Plaistow

station (actually sited close to Ifold). In order to

avoid tunnelling immediately north of Midhurst

the line had to approach from the north-east so serving the villages of Kirdford and Lodsworth.

Midhurst to Chichester would

have been under construction at this time but with this new line now laid as

double track through Cocking tunnel and Cocking

station to Singleton (with its four

platforms and nearby Goodwood racecourse) to a junction just west of East Dean.

However, Singleton to Chichester was

probably still laid as a single track providing a useful route towards

Worthing, Hove [actually] and Brighton.

West from Singleton the line may have entered two

further tunnels (under Heathbarn Down thence

Stoughton Down) necessary to provide a fast alignment into Havant. This could

have given rise two further stations (Stoughton

& Walderton thence on a falling grade to Westbourne). The Brighton to Portsmouth

Railway was joined just east of Warblington.

The

possible route is described in detail here at the bottom of

this article.

This made Ewhurst Green

(Surrey) a respectable candidate for the model railway.

|

|

|

|

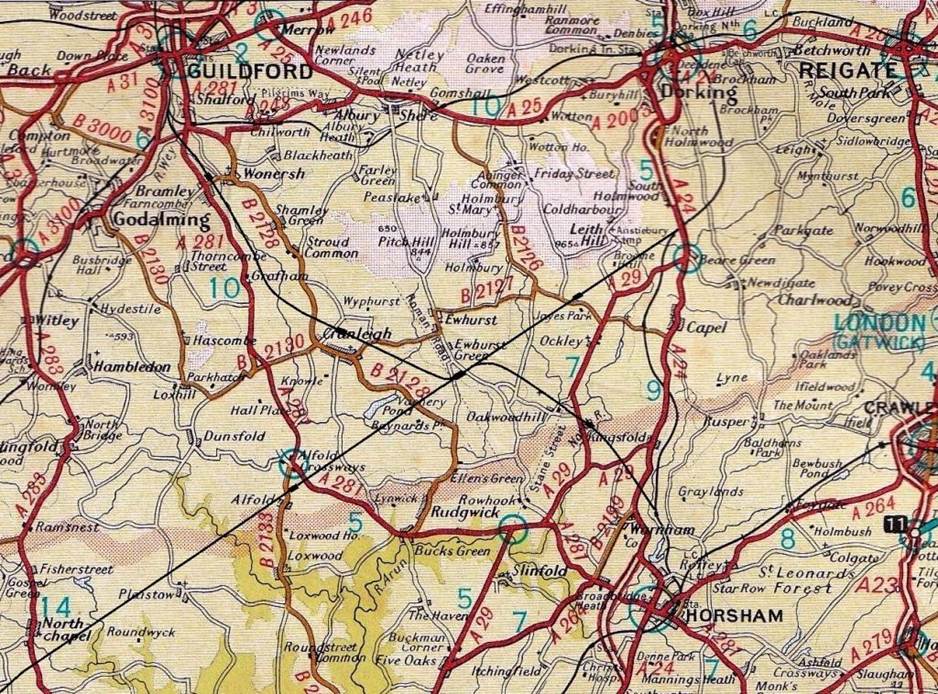

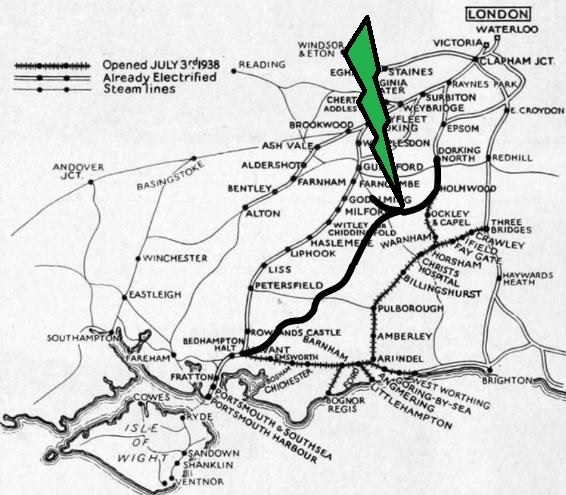

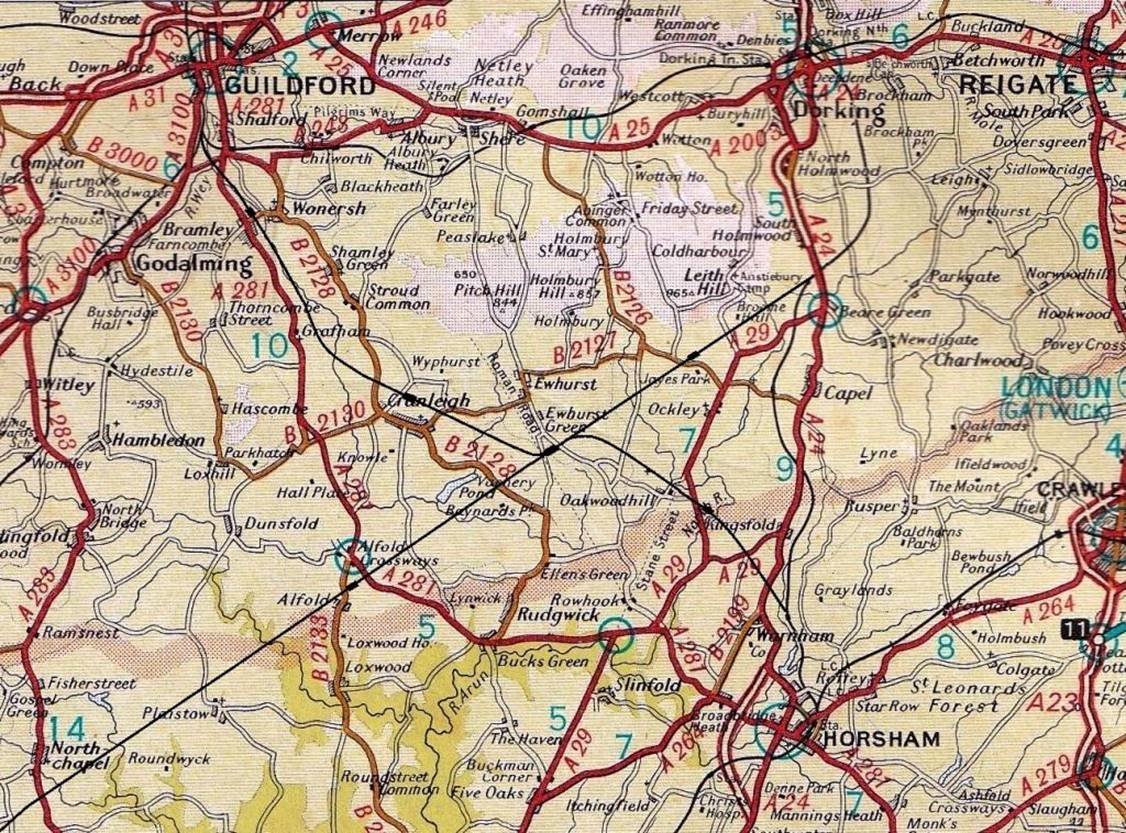

Route map shewing the

railway from Dorking through Ewhurst Green with the branch to Guildford via

Cranleigh thence Bramley & Wonersh also the branch to Horsham via

Oakwoodhill and Warnham. |

|

Local Development due to the Railway

As a junction with a railway through to Cranleigh

(thence onto Guildford and Reading via the SER route) Ewhurst Green could have

grown significantly through being served by (in time) an electrified railway.

So, it eventually became a starting point for suburban services into London

(along with some freight handling).

Nearby Cranleigh doubled in size in the first forty

years after the building of the 1865 Guildford to Horsham railway line and it

is probable that Cranleigh would have grown much further had it been on a

direct railway line /service to London (thus being attractive to commuters).

With rail congestion in Guildford’s southern approach, an alternative

route from Cranleigh to London via Dorking might have been an attractive

proposition post-grouping.

However, villages such as Ockley and Capel did not

grow as significantly; perhaps their respective distances from their station

and the slow low-frequency rail service made a significant contribution to this

lack of growth, particularly when the London suburbs were still expanding.

Any proposal for a branch to Holmbury

St. Mary was never a credible prospect; even local bus services were not that

frequent.

Midhurst could also have grown significantly from

having direct routes to both London and Portsmouth, it is also probably that a

few of the villages with stations along the line would have experienced some

increase in size. However, it must also be noted that it was only in recent

years did many places served by the Mid-Sussex line (a.k.a

Arun Valley line) south of Horsham undertake significant development.

Accordingly Ewhurst and Ewhurst Green could have

similarly expanded, particularly around a well-served station.

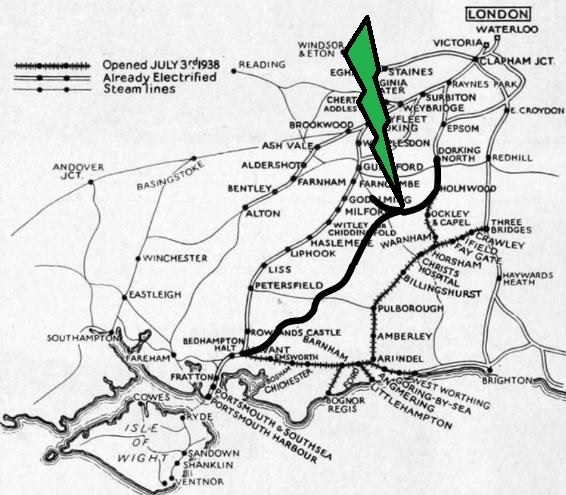

The building of such a route (including its

subsequent early-1925 electrification as part of the Waterloo to Dorking

scheme) could have led to interesting connotations in respect of railway

service patterns although in reality Ewhurst Green (plus Ewhurst and Walliswood) would probably never have grown to sufficient

size to be as busy as portrayed by the model.

|

Route map shewing the

railway from Dorking |

Route Engineering

Imagination could reasonably assume this route was

reasonably well-engineered being intended to provide a faster alternative (to

the Mid-Sussex line) between London and Portsmouth as well as competing with

the LSWR’s Pompey Direct; - a 1858-built and privately constructed

curvaceous and graded line south from Farncombe (that was offered for sale to

the LSWR, LBSCR and SECR).

In determining the route (and with a background in

railway /tramway alignment design) the topography was examined to confirm such

a route would have been reasonably practicable.

In terms of distance this route would have been

around ten miles shorter from Victoria to Havant than via Ford and only around

three miles longer than Waterloo to Havant via Guildford.

In Southern Railway days this imaginary line could

have also provided a potentially viable route to Fareham with trains

terminating at either Southampton Terminus or Southampton Central.

Post-grouping could have also opened-up limited services into Waterloo via

Raynes Park (including as a useful diversionary route). Although quickly DC

electrified, like many places in Sussex its branches were not.

However, with this line having been opened it is

questionable as to how long Midhurst Pulborough and Midhurst Petersfield would

have survived; probably closing earlier than they really did. Midhurst

Chichester would have probably survived having strategic use as an east-facing

connection onto the Havant to Brighton line.

|

An unidentified

Birdcage trio C nears Gomshall

& Shere behind BR Standard 4MT no. 76054 on the 5.31pm Redhill to Reading South

service (1st June 1957). Ben

Brooksbank (Geograph/CC-by-SA) |

Dorking connections

Holmwood to Cranleigh & the coast (proposed)

On more than one occasion, the LBSCR

considered the provision of link between its Portsmouth mainline passing

through the rather isolated district lying to the south of Leith Hill and Pitch

Hill. The SER had similar aspirations of its Redhill Dorking route.

In 1897, plans were prepared for a

line from Holmwood to Cranleigh; a distance of about 8 miles. A bill was

submitted to Parliament in the ensuing year but was withdrawn in the face of

opposition from landowners in the Holmwood district. The scheme was never

revived.

Ewhurst Green model railway takes much

inspiration from this scheme.

Betchworth to Holmwood (proposed)

Early railway proposals at Dorking appear to have

included a line diverging from the Redhill to Reading railway across to

Cranleigh. However, there was never a connection linking Betchworth to Holmwood

as traffic would have travelled via Three Bridges. The question is would such a

spur been useful to connect to Ewhurst Green (etc) and the answer would have

probably been not unless part of a scheme to give the SER a route right through

to Portsmouth. However, there would have been great difficulty in obtaining a

viable route that would have satisfactorily served the town of Dorking

(including Deepdene station) given the topographical constraints of the area.

From Croydon, LBSCR passenger trains would have

been routed via Sutton /Epsom /Dorking although for the SER the journey time to

Dorking via Redhill wasn’t much different. However, if the SER had built

the line, then this spur may have come into being although come SR days it

would have probably found little favour with Waterloo providing the faster

services to Portsmouth.

Freight from (say) Norwood Yard would just have

easily reached Ewhurst Green via West Croydon. However, had there been direct

connection across the top to Tonbridge at Redhill then the situation may have

been very different for traffic to /from Kent into Hampshire.

Deepdene to Holmwood (spur closed)

There was a spur linking Deepdene and Holmwood

(closed 1900 /reconnected 1941-47). This only ever appears to have seen minimal

use very early-on for South Eastern Railway race-trains to Epsom.

However, during 1941-1945 it’s reconnection

onto the Redhill Reading line (since 1900 it remained as a siding off the

Horsham line) could have provided alternative routings in the event of

blockages (including from enemy action); in particular, enabling the movement

of breakdown cranes.

Was it therefore plausible that this spur may have

been retained in 1900 to create a means of diverting freight traffic to Ewhurst

Green instead of through Cranleigh? Probably not as there would have been

little or no commercial need. Furthermore, freight use would be restricted by

the steep grades away from Deepdene up to Gomshall thence down to Shalford

(each around 1 in 100); particularly with more practical routes being

available.

|

LMS-type

Ivatt 2MT No. 41301 runs around down Horsham’s platform 3 having just

arrived on a service from Guildford on 5th June 1965. Ben

Brooksbank (Geograph/CC-by-SA) |

Horsham connections

The Guildford Cranleigh Horsham railway provided a

cross-country rural railway with onward connections to London (and other

destinations) at both Guildford and Horsham. However, with the building of and

connection to Ewhurst Green would bring changes including potentially splitting

the services from Guildford and Cranleigh between terminating at Ewhurst Green

and Brighton (via Horsham). Such a layout would mean any though traffic from

Reading (and beyond) to Brighton via Horsham & Henfield was not constrained

by the actual need in reality for changing /reversal at Horsham (else

inconveniently changing at Christ’s Hospital) to continue onward to

Brighton via Henfield.

Although there was a spur at Christ’s

Hospital enabling trains to travel directly from Cranleigh to Ichingfield Junction thence to Brighton via Henfield, this

appears to have been taken out of use before WW1. In addition, the spur could

not serve Horsham or provide any passenger interchange onto the Horsham to

Arundel railway which no-doubt contributed to its demise.

There were three stations between Cranleigh and

Christ’s Hospital: Baynards, Rudgwick and Slinfold. In terms of Baynards Park estate this is located

equidistant between Baynards and Ewhurst Green stations and there would

probably have been minimal case for Baynards station. Passengers for Rudgwick could have changed at Ewhurst Green else Alfold.

It is therefore possible that one of five options

that may have occurred:

1. The

line through Cranleigh passed to the north of the town to Ewhurst Green and its

main line. Immediately north

of Ewhurst Green there was another junction for a line heading south-east

passing through a station at Oakwoodhill before joining the Dorking to Horsham

railway line at Warnham. This would provide a cross-country direct route

(without reversal) from Reading - Guildford Cranleigh via Ewhurst Green through

Horsham and onto Brighton.

That the spur at Christ’s Hospital was taken

out very early on the viability of such a connection without serving Horsham

was probably highly unlikely. Rudgwick and Slinfold would have been served either from Horsham or

Ewhurst Green or did the main line serve Rudgwick

instead of Alford...

2. From Cranleigh the railway would have simply been

constructed to Ewhurst Green instead of reaching Horsham. With Ewhurst Green

being close to Baynards the case for a station there could be much reduced; the

actual need for Rudgwick and Slinfold

stations also needing consideration.

3. The Guildford - Cranleigh - Guildford railway (it

was named Cranley up to 1867) was constructed with a spur from Cranleigh to

Ewhurst Green. With Ewhurst Green close to Baynards the case for the latter

station could have been much reduced.

4. The railway would have provided a spur south off

the Ewhurst Green Alfold railway south-east down to join the Cranleigh Horsham

railway close to Baynards station. This option would have meant Cranleigh to

Horsham trains could call at Ewhurst Green (albeit with a reversal) thence at Rudgwick and Slinfold. However,

the viability of such a spur was probably questionable both operationally and

in terms of journey times for Guildford /Cranleigh passengers to /from Horsham.

5. The two railways would have

simply crossed. However, it is unlikely that the potential for a faster

Cranleigh to London connection would have been ignored by the LBSCR.

In respect of the model’s station operation,

it is assumed option 1 had been implemented.

|

Hawker Hunters parked outside the final assembly hangers situated on

the northern side of Dunsfold Airfield. |

Dunsfold Airfield

Built in just twenty-weeks during 1942 by the First

Canadian Army (mainly the 2nd Battalion Royal Canadian Engineers), it is

conceivable that Dunsfold Airfield could have served by a lightly-laid

freight-only branch from a well-connected main line (in reality no such facility was ever provided off the nearby Horsham to

Cranleigh branch line).

Accessed from Cranleigh, the branch curved

significantly to follow the land topology (in order to speed construction and

reduce cost) across Cranleigh Road (close to Elmbridge Road) in part following

the route of the Wey & Arun Junction Canal (by 1868 canal traffic had virtually

ceased with an Act of Abandonment passed in 1871) until it turned to cross Horsham Road near the

northern end of the (then new) Alfold by-pass (itself built to accommodate the

airfield) and into the airfield.

RAF - Dunsfold Airfield was used by the

Royal Air Force, Royal Canadian Air Force & the Royal Dutch Naval Air

Service. At the end of the war Dunsfold Airfield was used for the repatriation

of PoWs (Operation Exodus) before being declared as inactive.

Skyways - In August 1946 the airfield was

leased to Skyways Ltd as a 24-hour operations & engineering base. Skyways

Ltd employed some 1200 staff (including 350 aircrew) at Dunsfold; its principal

air-charter work being transportation of Anglo-Iranian Oil Company staff into

and out of Basra and (from June 1948) the Berlin Airlift. Unfortunately, the

end of the Berlin Airlift in May 1949 saw some 400 staff being made redundant

and in March 1950 Skyways Ltd went into liquidation. It was relaunched but this

failed in January 1952. Taken over by the Lancashire Aircraft Company in March

1952, Skyways moved to Bovington (presumably to make more room for the Hawker

Aircraft Company). After further changes the final iteration of the company

ceased in 1962 with the Skyways name disappearing in 1980.

Hawker - In 1951 the Ministry of Supply

offered the Hawker Aircraft Company the lease of Dunsfold Airfield which was

then used for the development of the delta-wing Avro 707B, Hawker Hunter and

Sea Hawk jet fighters. In addition, Sea Furies, North American F-86 Sabres and

Supermarine Attackers were refurbished at the airfield (the latter pair in two

hangars leased to Airwork Ltd from 1953-58). In October 1960, Hawker Siddeley flight tested its Hawker P.1127 prototype (which

led to the Hawker Siddeley Harrier). In 1961 Folland

Gnat test flying, and production moved to Dunsfold from Chilbolton in

Hampshire.

Given the curving nature of this lightly-laid

branch (a consequence of its rapid construction) trainloads were inevitable

small with suitable motive power limited to short-wheelbase locomotives.

As a rail-served facility it could have initially

proven useful, particularly given its relative accessibility including MoD

sites such as Bicester, Marchwood and Shoeburyness; the latter being via the

East London Line (which saw freight use through to 1966). However,

post-war saw a significant reduction in freight traffic on the Dunsfold branch;

essentially now limited to occasional vans and aviation spirit to the Hawker

Aircraft Company.

hree

|

Lord Nelson no.30863 Lord Rodney on Down express formed strengthened set

247 Formed BTK-TK-FK-BTK set 247 is strengthened with Loose TK and TO coaches

plus New Century Bar Pullman car (now

replaced with a Maunsell restaurant car). |

3. Ewhurst Green & the

Southern Region

Passenger Journey Times & Possible Services

For any credible train operation (including its

timetable) the journey times to destinations served need to be fully

understood, enabling Ewhurst Green to be considered in terms of the traffic

that could be routed through it including realistic journey times.

Ewhurst Green station

When first built, Ewhurst Green had just two

platforms on the double tracked main line with a junction leading onto the

single-track branch to Cranley and Guildford.

At the request of the United Kingdom’s Postmaster

General, Cranley was renamed

Cranleigh in 1867 as it was often

mistaken for Crawley (and vice-versa).

As traffic increased, this route to Cranleigh was

double-tracked and an additional bay platform (now platform 4) provided at

Ewhurst Green, along with the new station (Myres) station building. With the

1925 electrification, all the platforms were extended southwards and a new

eight-coach platform 1 (Up Loop) provided for the electric suburban service

that would be starting from there.

Accordingly, the station has its platforms and

freight reception road arranged as follows:

|

(a) |

Freight reception used by freight traffic, shunting

into the carriage siding and entry into the goods yard. |

|

(b) |

Platform 1 - Up Passenger Loop is used both

for terminating /through traffic off the Cranleigh branch and terminating

suburban electric services from London. There is also direct access into the

8-car electric siding. |

|

(c) |

Platform 2 Up Main |

|

(d) |

Platform 3 Down Main |

|

(e) |

Platform 4 non-electrified bay platform used

to provide a connection from London trains across the main line and onto

Cranleigh branch services. |

|

(f) |

Dock - accessed from the Down Headshunt. |

|

Note |

Platform 1 is Ewhurst Green’s only

reversible platform road whereas platform 4 is for departing services only. |

Route to Portsmouth

Back in the real world, for many years some of

Victoria’s services to Bognor Regis and Portsmouth were routed via

Dorking North (some 2hr 15min to Portsmouth Harbour compared to 1hr 35min on

the Pompey-direct from Waterloo) until they included the stops at East Croydon

and Gatwick Airport with the May 1978 re-routing of services.

A faster route via Ewhurst Green might have reduced

this 2hr 15min Victoria time by some 10 or even 15 minutes; even more without

many of the Arun Valley /Chichester stops. Certainly, some of the fast trains

to Horsham (and beyond) that used to run via Mitcham Junction (non-stop) and

Dorking were around 10 minutes faster than the present services routed via

Gatwick Airport.

It is therefore presumed that this imaginary new

line via Ewhurst Green might have just managed Portsmouth Harbour in 1hr 55mins

for fast trains either from Victoria or Waterloo; the journey from Waterloo via

the Pompey-direct being some twenty minutes quicker (1hrs 35mins). Whilst

Waterloo to Dorking was 46 minutes for the fastest suburban services, like

Victoria a non-stop journey could be 37 minutes.

The stopping journey time to Portsmouth via Ewhurst

Green would have been around 2hr 25mins, this being some 50 minutes longer than

the fast train from Waterloo (today’s services via Eastleigh and Fareham

taking around 2hr 10mins). Obviously the stopping trains served different

communities.

|

T9 no.30119 hauls Mk1

set 876 on an Up Waterloo service; this set being released new from Eastleigh

Works on 1st June 1952 in Crimson Lake & Cream livery. |

Route to Fareham & Southampton

Modern Victoria services to Southampton are more

about intermediate trips (in particular as they include the now-important

interchange at Gatwick Airport) rather than overall end-to-end journey time (today’s trains from Victoria right

though to Southampton being routed via East Croydon, Gatwick Airport and

Horsham).

Until the advent of electrification from Farlington

Junction to St Denys (in May 1990), very few trains ran direct from Havant to

Fareham; this line would have provided a regular through service without the

need to travel to Portsmouth & Southsea to change (the Waterloo fasts did

not stop at Fratton). Operating a service via Ewhurst Green would improve this

connection and give Fareham a London service but not at the expense of South

Western main line capacity between Basingstoke and Eastleigh.

In terms of London to Fareham, a route through

Ewhurst Green would have probably been achieved in 2hrs; being far quicker than

changing at Eastleigh and marginally quicker than changing at Portsmouth &

Southsea (today’s direct electric

service via Eastleigh take 1hr 35mins). Accordingly, on this model there

are regular steam services from London direct to Fareham thence onto

Southampton; these also serve the Cosham, Netley and Woolston which were (then)

comparatively large compared to other station-communities along this section of

line.

Would such a service have saved the branch to Fort

Brockhurst and Gosport? - probably not.

Cross-country Services

Ewhurst Green was one of several junctions on the

cross-country route from Brighton through Horsham to Guildford and Reading with

some services through to Alton and beyond.

Local cross-country services ran though Guildford

and Tongham to Bordon.

Race days at Goodwood also saw regional and

interregional services.

London Commuter Traffic & Cranleigh

Dorking North’s suburban services took around

37 minutes from Victoria (limited stops), 46 minutes from Waterloo and 53

minutes from London Bridge.

From London’s Victoria station, Ewhurst Green

would probably have been around 5 minutes shorter than the 53 minutes to

Horsham (timing for those trains that only stopped at Dorking North); 50

minutes from Victoria could have been achievable. This could have placed

Cranleigh at just under an hour from London on the through service (50 minutes was just achievable on selected

services from Waterloo changing at Guildford although this was often closer to

an hour). Given the how busy Guildford station was (and still is) it is

conceivable that Cranleigh London services were routed through Ewhurst Green,

including during the peak-hours.

|

On the Branch reversible, Somer

(12mm/1ft black /white tuxedo livery) simply isn’t fazed by Schools

class no.30913 Christ’s Hospital (4mm/1ft BR Green livery) passing by

on the Up Line with visiting Pullman cars. Somer often curls up in a little box just under the

baseboards sleeping quietly despite all the trains rumbling overhead! |

4. Station Operation of the Model

The larger the layout the more there is to control, and one can only realistically hope to control one or two trains at any given time. The station layout comprises Up and Down Main lines with an Up Loop (for steam services off the branch and the start of suburban electric trains into London) and a Down Bay essentially for starting steam services onto the branch to Cranleigh and beyond.

In terms of signalling, home signals are normally

situated 440yards out from the station; this would place those for Ewhurst

Green in the fiddle yard /storage loops effectively meaning there is only scope

for having one train running on each circuit at a time. With the branch

operating from the Up Passenger Loop there is scope for a further train

operating. However, such complexity would require multiple operators.

In essence, the main line (with its through trains)

provides the window dressing for the main operational side to the layout, steam

services off the branch and the suburban services. A modest up-side freight

yard also provides for a diversion of interest.

Furthermore, I anticipate the option of operating

the layout to time rather than a sequence necessary to entertain at exhibitions

(neither my cats nor I get bored with the gaps between trains).

Chapter Five

|

An unidentified 4 CEP unit undertakes

conductor-rail clearance testing on a newly laid section of con-rail. Soon

after this photograph was taken the section of con-rail was lifted, primed,

painted and re-laid back in place. |

5.

Passenger Service Pattern

In designing a layout, it is important to consider

how it could operate in a reasonably realistic but interesting manner.

Certainly, most of the Southern Region’s electric services operated on a

half-hourly clockface pattern; this in part being down to the economics of DC

third rail operation.

Portsmouth

Some 50 minutes from Victoria, Ewhurst Green would

sit upon a basic hourly semi-fast electric service from Portsmouth Harbour to

Victoria; services serving Midhurst, Havant, Fratton and Portsmouth &

Southsea (calling all stations between Ewhurst Green and Westbourne).

Warblington was served by the Chichester to Havant services.

Set atop of this basic hourly electric service was

an hourly fast electric service Victoria Portsmouth Harbour via Havant, Fratton

and Portsmouth & Southsea (which did not stop at Ewhurst Green). The

platforms at Ewhurst Green are configured electrically to enable the splitting

/coupling of electric units should the service pattern alter at some future

date.

Fareham & Southampton

There would have been an hourly steam-hauled

Victoria Southampton fast service passing through Ewhurst Green running via

Havant to serve Fareham; a significantly-sized town which (following the

opening of the Pompey-direct) did not then enjoy a regular direct service to

London. An additional peak-hour service ran from Waterloo. It is envisaged

these Fareham /Southampton services would (at set times) contain dining

facilities /Pullman car.

London Commuter Traffic

Situated at the end of suburban services, there was

just an hourly off-peak stopping service to London Bridge (the other

half-hourly suburban service terminating at Dorking North). With the exception

of the London Bridge stoppers, rush-hour fast services travelling north would

just call at Dorking, semi-fast additionally at Leatherhead, Sutton and Clapham

Junction.

Forest Green station would only be served by the

hourly London Bridge suburban service; Holmwood by Dorking to Horsham trains.

Cross-Country

Guildford, Reading, Horsham & Brighton

On the Guildford branch there would be a

half-hourly service; one loco-hauled each hour from Brighton (via Horsham)

through to Cranleigh, Guildford and Reading with the other rail motor

(pull-push) from Ewhurst Green terminating at Guildford; prior to 1957 this

having continued to Wanborough, Ash, Tongham, Farnham, Bentley and Bordon.

Additionally, there was a rush-hour service (loco-hauled) from Cranleigh into

London Bridge.

There was also a couple of through services from

both Brighton and Horsham through to Guildford thence onto Alton, Winchester,

Eastleigh and ultimately Southampton Terminus, although not advertised as such

in the public timetable. These were mostly for the carriage of mail and

newspapers, although still carried local passenger traffic.

All this is of course concocted simply to make

interesting railway operations rather than any probable commercially viable

service!

Chapter

Six

|

Against the backdrop of the single-story

agricultural-based works, E4-class no.32503 hauls BR(S) CLC-liveried Mk1 3

Cor set no.525 on a Down train. |

|

Time |

Up Departures |

Time |

Down Departures |

|

xx.02 |

Victoria calling at: Dorking North Fast train from Southampton Central formed two no. 3-car loco-hauled

sets (Platform 2) Some of these services additionally include a restaurant car or

Pullman dining car. |

xx.03 |

Guildford calling at: Cranleigh Stopping train starting here formed rail motor (pull-push) else 2 LAV

set (Platform 4 Down Bay) In later years this service terminated at

Guildford. |

|

xx.12 |

Arrival from Bordon. Terminating here formed rail motor (pull-push) else 2 LAV set (arr Platform1 shunts to Platform 4 Down Bay) |

xx.14 |

Portsmouth Harbour calling at: Loxwood Semi-fast train (headcode 50) formed three no. 2-car emus

(Platform3) |

|

xx:22 |

Victoria calling at: Dorking North Semi-fast train (headcode 50) from Portsmouth Harbour formed three no.

2-car emus |

xx.28 |

Arrival from London

Bridge Suburban stopping train (headcode 29) terminating here formed 4-car

emu(s) having detached 4-cars at Dorking North (Platform 1). |

|

xx.34 |

Passing time Dorking North Fast train (headcode 46) from Portsmouth Harbour formed two no. 4-car

emus (Platform 2) |

xx.34 |

Reading (Southern) calling at: Cranleigh From Brighton via Horsham formed 3-car loco-hauled set. |

|

xx.42 |

London Bridge calling at: Forest Green Suburban stopping train (headcode 29) starting here formed 4-car

emu(s) attaching at Dorking North to form 8-car to London Bridge. (Platform

1) |

xx.43 |

Passing time Havant Fast train (headcode 46) formed two no. 4-car emus |

|

xx.47 |

Brighton calling at: Oakwoodhill Warnham Horsham West Grinstead Partridge Green Henfield Steyning Bramber Shoreham-by-Sea Hove Semi-fast train from Reading South via Guildford & Cranleigh

formed of 3-car loco-hauled set (Platform 1). |

xx.54 |

Southampton Central calling at Midhurst Fast train formed two no. 3-car loco-hauled sets. Some of these services additionally include a restaurant car or

Pullman dining car. |

Electric

Train Headcodes

Southern Electric

services carry a two-digit route headcode. Older electric units used stencils

to display their headcodes and as each motorman’s cab only carried one

set of number stencils, headcodes using duplicate numbers (such as 11 or 22)

were not used until roller blind headcodes came into use; even then they were

initially allocated to diesel-operated services.

Ewhurst Green’s

services operated over both Central and South Western Divisions (they also ran

close to South Eastern Division services at Victoria and London Bridge).

Accordingly, the designated headcodes needed to take this into account.

|

Code |

Route |

Notes |

|

2 |

Dorking to Ewhurst

Green |

Morning peak-hour |

|

4 |

Waterloo to Portsmouth

Harbour via Bookham* |

*else Ewhurst Green |

|

16 |

Holborn Viaduct to

Ewhurst Green |

Rush hour service |

|

18 |

Victoria to Portsmouth

Harbour (stopping via Mitcham Junction) |

(Victoria Littlehampton services renumbered 28 ) |

|

27 |

London Bridge to

Ewhurst Green (via West Croydon) |

Code not used on SWD. |

|

29 |

London Bridge to

Ewhurst Green (via Mitcham Junction) |

Code not used on SWD. |

|

46 |

Victoria to Portsmouth

Harbour (fast via Mitcham Junction) |

(Victoria Bognor Regis |

|

50 |

Victoria to Portsmouth

Harbour (semi-fast via Mitcham Junction) |

(Victoria Littlehampton services renumbered 70 ) |

|

74 |

Waterloo to Ewhurst

Green |

No conflict with CD or SWD. |

|

82 |

Victoria to Portsmouth

& Southsea (via Mitcham Junction) |

(Victoria to Crystal Palace services renumbered 66) |

Chapter Seven

|

In the autumn sunshine

the Crimson Lake liveried pull-push set |

External Passengers & People

For the

more-distant sections of the layout a few of Bachmann’s 4mm figures have

been used as these were simple and straightforward to fit. However, for the

station’s passengers and staff (in both the coal and goods yards) higher

a standard of professionally painted figures were procured from by Pete Goss.

Having rapidly

exhausted much of Pete’s excellent range of figures (including

differently painted duplicates to swell numbers), a further preparation and

painting order was placed comprising unpainted figures (mainly) from Dart

Castings and the now sadly defunct Aiden Campbell 4mm range (pleased

I’d the foresight to invest in these).

|

|

|

|

Selection of standing passengers |

Express Dairies milkman & crates |

Pete’s work

starts with trimming

off all those parts not required (much from the casting process), thence

drilling, pinning and assembling figures prior to placement in wooden holed

timber jigs. This enables the figures to be sprayed with etch primer prior to

painting with acrylic paint. Ultimately Pete provided a large number of figures

all with a significant consistency of appearance.

|

Mk1 CK fitted with Preiser’s

seated people. |

Internal Passengers

Arguably one of the

most import features of a model railway are the passengers and people; these

bringing the scene alive . Passengers within trains are reasonably

straightforward and even with 4mm (OO) the use of 3.5mm (HO) seated people is

ideal as these sit well within the often overscale interiors.

Figures used from Preiser’s

unpainted range includes cat. no.16328 (120 seated figures) cat. no.16349 (36

seated figures for buses etc), cat. no. 16358 (72 seated figures) while

Faller’s equivalent is cat. no.1485 (again 72 figures per pack). When

search for these ‘seated people’ tends to display more

results than ‘seated passengers’.

Just under 3000

figures are now being painted by my son using Army Painter Speedpaint on a light grey primed surface (he will of course be well rewarded

for his hard work). This may sound a lot but when spread out across all the

coaches only averages around two per compartment!

Loading Gauge

Although the LBSCR loading gauge was reasonably

generous we will assume this route was out-gauged (along with Three Bridges -

Redhill- Reading) during the Great War to provide the LSWR with an alternative

route to Havant via Raynes Park and Epsom. Accordingly, with fewer curves and

gradients than the Pompey Direct, this route offered a viable route to

Southampton and Bournemouth; particularly for diversionary workings if (say)

Winchester St. Denys or Woking was blocked.

Diversity of Rolling Stock

Ewhurst Green (Surrey) could also provide a rare

opportunity outside of London for the mixing of rolling stock of the Southern

Region’s three divisions (SED, CED & SWD); some SED services coming

down from Reading.

Accordingly, coaching stock could include SED

Birdcage sets on services from Reading. Before the Second World War ex. LSWR

Gate-Stock operated to Guildford and it is not improbable that other ex. LSWR

coaches would have reached Ewhurst Green (either from Guildford or Waterloo to

Cranleigh via Dorking). During the period modelled, Maunsell and Bulleid 59

multi-door 3 COR sets were used in the area along with other Pull-Push stock

including the Maunsell pull-push conversion sets.

The main line would have used electric suburban

units (terminating) and lavatory stock down to the coast but needed locomotive

hauled sets to travel west from Farlington Junction to Fareham and beyond.

The layout easily manages twelve-car non-stop

trains on the main line (for example Portsmouth Harbour twelve-car train of 4

BEP /4 CEP /2 HAP units) thirteen cars if an MLV is present. However, visually

eight coaches maximum appears to visually work best whether this be an electric

train or a locomotive hauling (say) two number BR(S) three-car coach sets

(perhaps with vans) or longer sets with a buffet /Pullman car inserted.

In order to achieve these services, the two main

line through platforms (2 & 3) would be able to handle twelve-car trains

although the actual platforms are only ten-coaches long; most trains usually

being eight-car 2 BIL /2 HAL or 4 CEP /2 HAP formations. Used mainly for

departing branch services, the non-electrified Down Bay (platform 4)

comfortably handles six-coach lengths; branch trains being shunter across to

clear platform 1 and provide a convenient interchange between platforms 3 and

4.

Electric Trains

4 SUB (inc. augmented 3 Car Motor Units), 2 NOL,

and 2/4 EPB (BR & SR types) units all operate the four and eight-car

stopping services up to London Bridge and several peak-hour suburban electric

services ran into Waterloo from Ewhurst Green, joining the South Western main

line at Raynes Park.

The Portsmouth Harbour services utilise 4 COR /4

CEP /2 HAP units on the fast (non-stop) services with 2 BIL /2 HAL combinations

on the semi-fasts with 4 BEP units providing peak-hour catering facilities.

|

N-class no.31848 in its mid-fifties |

Locomotive-hauled Trains

Fareham and Southampton services variously use

Maunsell sets, Bulleid 59’ multidoor stock, Bulleid 64’ stock and

BR Mk1 corridor stock; a few of these services included dining facilities.

Locomotive-hauled set no.904 was redeployed from

the Oxted lines to operate one of the two peak-hour services into London Bridge

(routed via Dorking North and Peckham Rye). Weekdays this set would be kept

overnight at Ewhurst Green (along with an eight-car suburban emu formation)

running ecs to Guildford (reverse) to provide both Bramley & Wonersh and

Cranleigh with a semi-fast peak-hour train into London Bridge. After the

Saturday morning Up peak-hour train (at that time Saturday mornings were

part of the working week) the set was kept at Eardley sidings before

arriving back ecs on the Sunday afternoon. Originally six-coaches, set no.904

had its SECR TL replaced by two green Bulleid CK coaches so then comprised

BS-S-S-C-CK-CK-BS in Crimson Lake (these Mk1 coaches were repainted BR(S) Green

in 1958).

Reading Services

In terms of Reading services ex.SECR

Birdcage and ex.SR Maunsell sets were used along with Mk1 non-corridor 3-coach

sets displaced from Exmouth Junction services. Both the Reading and Guildford

services also used 2-coach rail motor (pull-push) sets; some strengthened with

an additional air-controlled coach.

However, all were now under threat from the new 2H

Hastings and 2H /3H Hampshire units on services through to Reading. By the time

the full Reading Tonbridge ‘3R’ service was implemented in on 6th

September 1965 the Reading to Ewhurst Green services had significantly reduced

to mostly a Guildford to Ewhurst Green shuttle.

Goodwood Race Days

Race days at Goodwood (served by Singleton station)

would see special trains down from London to Singleton with strengthened

connecting services from /to Reading. Often a spare Dover boat train formation

from Stewart’s Lane was employed (as happened on the Newhaven services);

often with the MLV still attached so as not to waste time detaching /attaching

(ironically the MLV was sometimes detached at Newhaven and used as a return ‘taxi’

to the driver’s depot at Seaford). Perhaps these spare boat-train

sets also operated several special-day services to Portsmouth or a specific

daytime service?

Still looking for a robust reason for including a

TLV yes, I know the MLVs & TLVs essentially operated on SED and the

latter is outside my era, but in 1968 number TLV S68203 did enter service in

lined maroon livery.

Similarly looking for a

reason to operate a 10 BEL formation,

perhaps on a Race-special to Goodwood else a Special to Portsmouth Harbour?

Chapter Eight

|

Ronuk of Portslade produced polish and had a fleet of

two tanker wagons, these were expertly weathered by TMC from an original

photograph. Ronuk appeared to have two 3,500 gallons railway

tankers numbered 34 & 38; these carried white spirit between Esso at

Fawley and Portslade. Producing polish, Portslade’s Ronuk

factory was established in 1902 & rail-served from c.1920; the name Ronuk being an Anglicised form of ronak (Kurdish clear ) /ronaq (Urdu lustre ) /raunaq

(Persian). In the late

1950’s Newton, Chambers & Co. acquired Ronuk,

the Portslade factory was closed and production moved to

Sheffield. However, the Ronuk-company

brand-names Colton & Ronseal still survive. |

I’ve never worked out why Ewhurst Green was a

useful location for freight although is saw a degree of goods and container

traffic. This line could also have remained useful route for through freight

between places such as Temple Mills (ER) and Holloway Yards (ER), Hoo Junction

(SED), Norwood Yard (CED) and Southampton (SWD) as well as North Camp,

Chichester and Shoreham (CED) along the West Coastway

(via Lavant). Local freight facilities are provided at Ewhurst Green, although

their use is on the decline.

|

Z-class no.30951 on shunting duty. |

Dunsfold’s Airfield

Limited traffic is envisaged to service

Dunsfold’s wartime-built airfield (in particular delivering components

and aviation spirit) to the Hawker Aircraft Company. Little is written about

the line serving Dunsfold airfield (from near to Cranleigh). From this siding

the curving line crossed the wartime-built Alfold by-pass and into the

airfield. Given the nature of the spur and the reduction in post-war freight

traffic, trainloads were inevitable short with suitable motive power limited to

short-wheelbase locomotives (my excuse for locomotives such as a USA /B4 tank

engines).

Accordingly, (on the days freight services ran)

there were at most two trips down to the airfield; the early mornings saw

locomotive and tank wagon with the locomotive returning hauling vans. In the

evening loaded vans were taken down and the locomotive returned with the empty

tank wagon.

|

Visiting S15

no.30842 hauls a fitted freight through Ewhurst Green during the 4th

September 2021 running session. |

Facilities

Apart from the needs of the yard’s shunting

locomotives (coal stage), facilities were basic with just several water columns

at the station. Any locomotives that would need turning would have to trip

through to either Guildford or Horsham shed. It isn’t really plausible

that the Deepdene Holmwood spur (closed 1900 /reopened 1941-47) may have been

retained to create a loop for freight traffic in order to reduce the need for

(say) locomotive turning upon termination (from the Guildford direction).

Chapter Nine

|

Visiting stock

regularly gets to run on Ewhurst Green and here a pair of Blue /Grey 2 COM

units lead a plain Blue 2 EPB on the Up Main. The 2 COM units

nos.6213 & 6259 were the last pair to survive in service on 13th June

1995 with 6259 being the one chosen for preservation (reverting back to

5759). Although Bachmann made unit no.6238 in this livery it did not carry a

2 COM red cantrail band as its compartments had previously been opened out

into a saloon at Slade Green in April 1984. On the rear is

Blue 2 EPB unit 5764 which was facelifted to 6264 on 19th December 1994.

No.5764 ran in blue livery from 25th July 1969 and was outshopped in Blue

/Grey livery in February 1984. MLV no.68009 quietly sits between turns in the

Down headshunt. |

9.

Ewhurst Green after my Modelling Period

In just a few years the route was reduced to a basic half-hourly service to Portsmouth Harbour; stations such as Cocking and Stoughton & Walderton being closed with others (for example) Singleton being reduced to rush-hour and race days only.

The line through Ewhurst Green would have probably

hastened the 1955 closures of Midhurst to Petersfield and Pulborough (serving

only Petworth) to pre-war (WW1), the route to Guildford closed in 1965 along

with the Midhurst to Chichester passenger services (which had survived because the sturdier embankment near Cocking

hadn’t collapsed).

The through Fareham /Southampton services were

gone; even the London Bridge service was reduced to just two trains each

morning /evening peak-hour as an extension from Dorking North (these now being

the only services to call at Forest Green). The only freight traffic left was

through trains; this still being a useful route to Portsmouth and Southampton

taking the pressure of the curving steeply graded Pompey-direct and the SW main

line.

Did this electrified line succumb to closure or is

it simply difficult to find in timetables?

Chapter

Ten

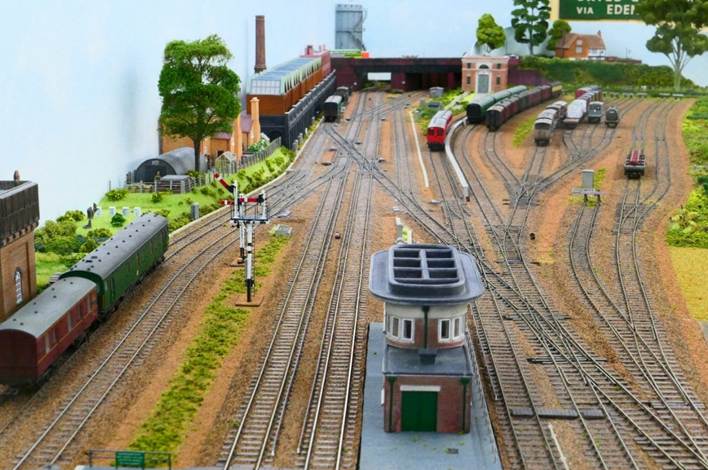

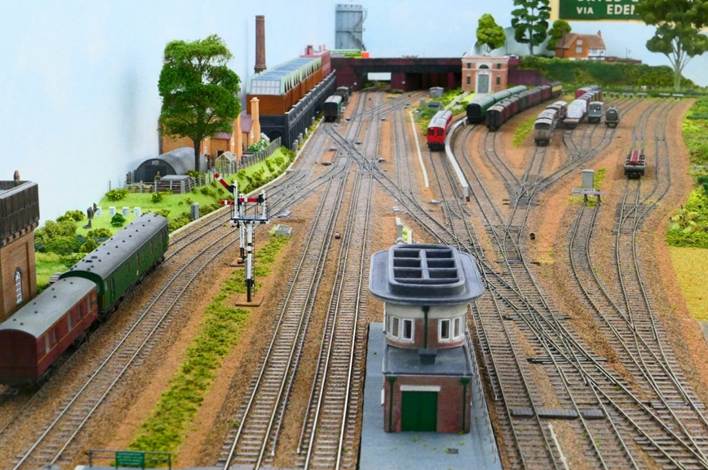

|

London end of the layout after construction |

Layout sizes can sometimes be physical too small in

terms of the station being modelled and a degree of compression is (usually)

inevitable. So, I’d considered basing my model on stations such as

Groombridge /Barnham /Ford /Horsted Keynes /Lingfield /Dorking North (etc).

That is two through platforms (2 & 3) and an Up Passenger Loop (platform

1). Alongside the Up Passenger Loop would be freight reception road similar to

Redhill - plus a shunting road in the yard.

On the Down side (country-end) was a short 6-coach bay (platform 4) and adjacent dock served from a headshunt. With no main signalled route into the bay, it was only ever intended to provide a cross-platform interchange to Cranleigh off trains arriving from London.

Barnham, Ford, Groombridge and Horsted Keynes

stations had a similar layout located on or close to junctions (which can lead

to much operational interest). Essentially the mainline will operate as Up and

Down circuits (with the possible splitting /joining of electric trains in the

through platforms). However, it is the branch (with its through and terminating

services) that will see the core operational interest on the layout.

Essentially platforms 2 & 3 would see the

through services (both Branch and Main) with suburban services from London and

Branch services terminating in platform 1. Also arriving in platform 1, local

Branch services would then shunt across to platform 4 to restart their journey

(similar operational moves took place at

locations such as Oxted and Eridge).

It was decided to place the main station building

towards the rear of the baseboards on the Down side. Besides placing the

platform-side of the building on view, this also left uninterrupted space along

the front of the baseboards for the Up Passenger (platform) Loop (where branch

trains would be terminating) and the goods reception road and sidings (i.e. all

within easy reach). Accordingly, the model’s operator looks south-east

towards the station.

This station concept provided the basis of the

baseboard design.

Enlargement of the Station

However, it doesn’t end there as the history

of the station can be seen in the model; many stations undergoing change across

the decades. When the railway was originally, built Ewhurst Green station was

double-tracked with two four-coach-long brick-built platforms, a Down-side dock

along with a larger Up-side goods yard.

Electrification would have led to enlargement of

the station to accommodate the terminating of 8-car suburban electric services

plus now a greater need for interchange facilities onto the Cranleigh branch.

This would have needed an Up Passenger Platform Loop and Down Bay (for

departing Cranleigh branch trains).

So, the mainline platforms were lengthened and a

6-coach Down Bay created at the expense of most of the small Downside goods

yard. Without a costly rebuild (plus additional /difficult land-take beyond) Somersbury Lane overbridge created a limitation in respect

of the headshunt for shunting back into the remaining goods siding and dock.

With the factory standing atop the cutting, in order to enable a headshunt to

be taken up to Somersbury Lane overbridge, this

cutting had to be dug out and replaced with a retaining wall.

The Up Platform was widened to meet a new Up

Passenger (platform) Loop capable of holding an 8-car electric train and the

London-end yard entry amended accordingly. The Up Passenger (platform) Loop

stopped short of the Up-side subway buildings as only an 8-car length was

required. South of the new Platform Loop an 8-car electric siding was created

along with an equivalent length carriage siding.

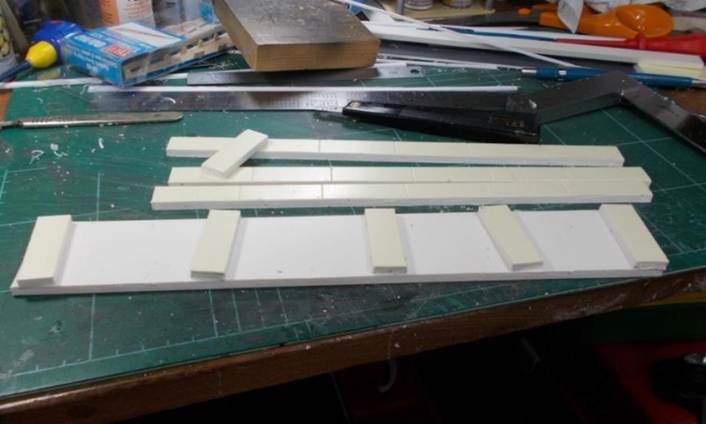

These new works was undertaken using concrete harp

& slab construction technique as supplied by the Southern’s Exmouth

Junction concrete plant. Re-signalling took place and a few years later the

main signal-box was replaced; the ex. LBSCR London-end box remaining as it

oversaw the level-crossing.

|

With tracklaying in progress and the retaining

wall planned Ivatt no.41250 passes pull-push set 610 (being propelled by

no.31518). The final retaining wall (Bachmann) differs from the (Hornby) wall

here and single story industrial buildings were more in keeping than the

three floor building. |

11. Storage Loops & Fiddle Yard Layout

Storage loops and fiddle yards can be a significant

part of a model railway for these represent the rest of the UK network enabling

trains to leave Ewhurst Green returning later in the day.

Trains entering the storage loops are kept there

until needed again; some will set back to Ewhurst Green whilst others will move

along the storage loop until it is their time to reappear. Some loop-lines each

store just two long trains whilst others can store six shorter trains.

For the Cranleigh branch the fiddle yard comprises

four tracks nearest the operator, and these involve reassembly of formations

including a simple changing end of locomotives. The Cranleigh branch also has

two dedicated storage loops capable of holding ten trains on each.

The storage loops and fiddle yard have six distinct

sections:

|

(1) |

Down Main storage loops (total 5 no. + 4

additional loops), |

|

(2) |

Up Main storage loops (total 5 no. + 4 additional

loops), |

|

(3) |

Up and Down Branch storage loops (one each), |

|

(4) |

Branch Terminating (two 6-car tracks), |

|

(5) |

Branch Terminating (two 5-car tracks) & |

|

(6) |

Locomotive depot. |

These are all designed to permit realistic

operation of the station with a combination of through and terminating

services.

|

(1) |

Down Main |

The Down Main storage loops comprise total nine

loops; five loops numbered 1, 2, 3, 4 & 5 to start with then two further

loops each off roads 1 and 5 (numbered 1a, 1b, 5a & 5b). These are capable of taking full-length trains

although some are electrically subdivided to accommodate eight and six-car

(equivalent) lengths (say eight-car emu formation or locomotive plus two

three-sets and luggage van or buffet car. |

|

(2) |

Up Main |

The Up Main storage loops (6, 7, 8, 9 & 10

plus 6a, 6b, 10a & 10b) replicates the Down Main albeit for travel in the

opposite (anti-clockwise) direction. |

|

(3) |

Up and Down Branch storage loops |

The Up and Down Branch storage loops (11 &

12) are just double track split into sections each being five-car

(equivalent) lengths (say locomotive, three-car set and luggage van). Alternatively, two loops together could

accommodate a train of ten-car lengths. |

|

(4) |

Branch Terminating |

Branch Terminating loops 13 & 14 (6-car fiddle yard) accommodate five

number trains up to six-car (equivalent) lengths. Although intended to

terminate /return stock into the south end of Ewhurst Green it is capable of

terminating trains from the north end of Ewhurst Green. It also includes a four-car length loop for

electric trains terminating from the north end of Ewhurst Green. |

|

(5) |

Branch Terminating |

Branch Terminating loops 15 & 16 (5-car fiddle yard) accommodate six

number trains up to five-car (equivalent) lengths terminating /returning

stock into the south end of Ewhurst Green. It also has two storage sidings (16a & 16b)

of three-car (equivalent) lengths for the storage of Pull-Push formations or

diesel electric multiple units. |

|

(6) |

Locomotive Depot |

Accessed off roads 13 to 16, the Locomotive Depot

comprises a non-scenic turntable serving both of the Branch Terminating

fiddle yards with storage for locomotives. |

More on this later.

Chapter Twelve

|

With HA E5001 on the test circuit, USA tank

no.30069 tries the (then) |

The layout is housed in a dedicated purpose-built

and well-insulated studio; the temperature running at a constant temperature

from an inverter proving air-con /heating (well worth the investment and

surprisingly cheap to run).

Baseboard Height

The layout’s baseboard was built at a height

of 52” using 3” by 2” timber with the top made from 12mm high-quality

exterior plywood (as supplied by an excellent local timber merchant). In other

words, strong enough to rest or even sit on!

After much musing with good friend Ian, this figure

of 52” high had been derived from a number of factors; the main one being

able to look at the railway from a more realistic sideways viewpoint rather

than looking down from a great height onto train roofs. Ian uses a similar

height on both his Oxted and Redhill P4 layouts. It is also a convenient height

to duck-under when the drop-down door flap is up in use and trains are being

run.

|

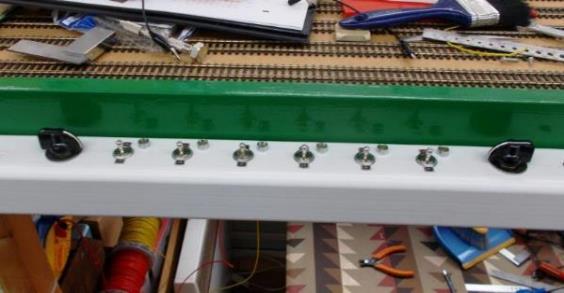

Prior to fitting of the layout’s green

facias, the fold-down flap in front of one pair of external doors. The end board is to protect rolling stock when

the flap is folded down out-of-use. The hardwood cill underneath the cats water bowl protects two 37-way

cables below. |

The height of 52” still places the rear of

the layout within practical reach whilst enabling tasks such as wiring and the

fitting of turnout motors (etc) to be undertaken from the relative comfort of a

swivel chair (until such time that I can

obtain a chaise-longue on raised legs with castors).

Furthermore, this height provides sufficient

clearance when leaving the trackroom with the flap

closed (trains running).

|

Terry undertaking construction |

Baseboard Width

Nominally 30” wide (the furthest one can

realistically reach and work), each corner has a triangular pop-up hole where

one can stand up to gain access.

Baseboard construction was undertaken by friend

Terry (a.k.a. the Rigger) who flew in from his mountain retreat in the Algarve

to construct the baseboards the lure of tea, biscuits and Cornflakes being

simply too irresistible!

Having constructed the boards for his own layout

thence Ian Sneyd’s P4 Redhill 1938, Terry has since gone on to construct a

friend’s baseboards for his 4mm take on the interesting arrangements at

Inverness.

Ewhurst Green’s fiddle yard boards were built

in March 2015 and the station boards completed October 2015. During the latter

visit the simple test circuit was also installed.

|

As part of his inspection, Moser patiently

undertook the first static load test of the baseboard |

|

Not to be outdone by Moser, Terry undertook the

same static load test |

However, on the station side the 30”

baseboards widen to around 50” at each end, which would ordinarily leave

the rear of the layout out of reach. The solution was simple in the form of two

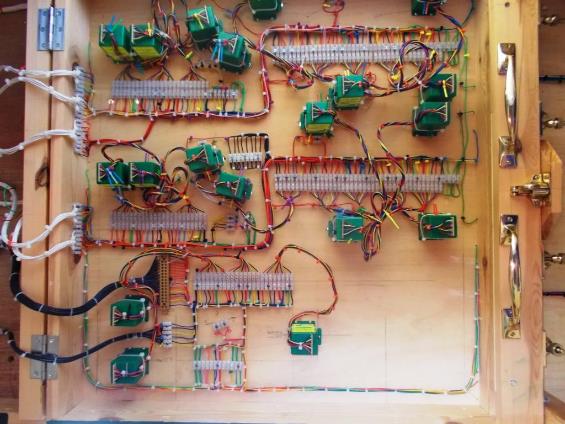

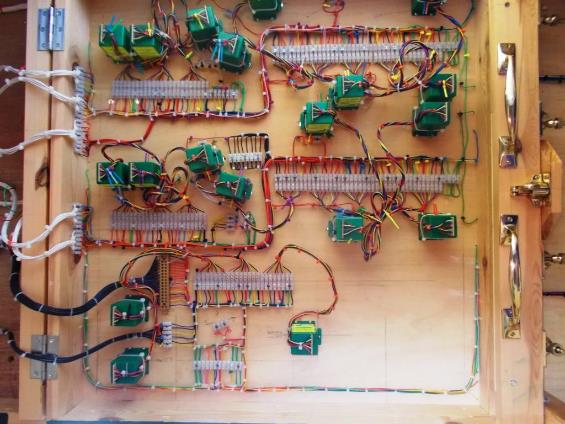

drop-down sections being provided (similar to the entrance door flap) to